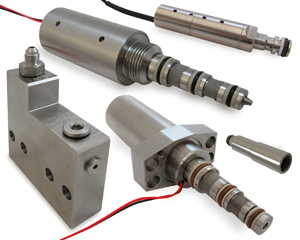

Most common valve types used in oils and gas market

In a piping system, valves are one among the essential parts. They are for regulating the pressure and flow in the piping system. The content of the current may be of gas, oil, liquid, or vapors.

Let’s look into some of the commonly used valves in the gas and oil market.

The globe valves are mainly used for cooling water systems. They are also used in transporting turbine lube and fuel oil systems as well. These valves fall in the category of linear motion valves, and they are suitable for regulating, starting, and stopping the flow. These valves come in use for isolation and throttling services. This is the most common type of pipe used in the entire world. This comes with excellent shut-off ability. Globe valves are available in wye, tee, and angle patterns. These valves mainly designed to help in stopping or starting the flow primarily in the straight-line fluid flow. These are best suitable when the requirement is to have minimum flow. Usually, when used, these valves also kept wholly closed or fully open. When this gate valve is turned on, the disc inside is entirely removed which allows contents to pass. This valve comes with excellent shut-off properties, and these valves bidirectional. When open, these are sensitive to vibration. Orbit valve is meant for turn and tilt operation, which helps in eliminating seal rubbing. This is the common cause of valve failures. When this orbit valve is in the closed position, the core is wedged mechanically tight against the seat which ensures positive shut off. When the orbit valve is opened, the heart tilts away from the place. This results in line flow to pass around the core face. So, it is easy to eliminate high-velocity flow, which usually results in reduced valve life and uneven seat wear. For starting or stopping the flow, plug valve makes use of the cylindrical or tapered plug. When the valve is open, the plug-passage will be in line with outlet and inlet ports. When the cap is rotated from an earlier position, blocking will be done by the substantial part and this result in stopping the flow. Plug valves are quite easy to turn off. These come with very small in size when compared to many other valve types. Plug valves have minimal resistance to the flow.

These pressure seal valves are suitable for pressured facilities. They are utilised more than 170 bars. Bonnet is the unique feature of these pressure seal valves. They come with a bolted bonnet which helps in sealing the valve along with a pressure seal gasket.

This is a quarter-turn rotational motion valve. The valves are mainly used for regulating, stopping, and starting the flow. They can be opened quickly, and they are straightforward to use. These valves equipped, and they usually come with a gearbox. This makes the operation easier but with the expense of speed. Butterfly valves are installed at least six pipe diameters away from the rest of the line elements. These are the lightweight, and the best part is they are quick to use. They are available in large sizes, and they can cope well with low-pressure drop and are also suitable for high-pressure recovery.