Types of instrumental check valves

Check valves are designed to prevent the flow of the piping. That may be in gases or liquid repair. These valves are made of metal and also soft valves. These valves help to attach the two pipes. The pressure of the fluid passing through the systems opens the valve. Check valves are essential for every factory, these valves are essential for every industry. Check valves are self-working valves. These valves prevent reverse flow. Check valves are automatic valves to check the flow of the water to go in one direction only. Check valves are made like the flow of the water did not run back format. This can also prevent the pipeline from damage. piston check valves are like the same to compare other valves. These valves are worked properly. There are five types of check valves in the market. These valves are also available in markets. Online shopping also available many companies buy products online.

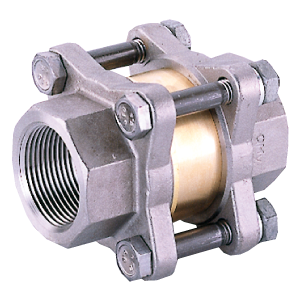

Ball check valves

A ball check valves are like rolling valves that can help to make clear the pipeline. The ball check valves have fit the ball. This made the valves comfortable that make the flow of the water in proper condition. This also controls the flow of the water in reverse. Ball check valves are self-cleaning as the ball rotates during operation. These ball check valves are tightness at minimum backpressure.

Diaphragm valves

Diaphragm valves the body with two or more ports in their diagram. This can use in different forms, diaphragm valves had many ways to pass the pipeline. The valves may be constructed from plastic and metal. There are two major groups of diaphragm valves, one type is weir valves this should be used to organize the water flow. The high purity application is the main benefit of the diaphragm valves. Diaphragm valves can be manual and automated. Automatic diaphragm valves are mainly used in many industries. Diaphragm valves are mostly many types this can help to develop the water flow.

Swing valves

A swing valve is a butterfly style valves in a well prepare model. The seat to allow the backflow of the water accurately. The seat open cross-section may be in proper connection. A swing system is used in many different manners and develop the proper water flow level. Swing valves are also available in Y pattern there we use more than two pipes for connection. Swing valves are made by metal and soft valves. Swing valves help the engineer to reduce their work. These types of valves can do most of the works automatically. Swing check valves are also made in various sizes like long check valves.

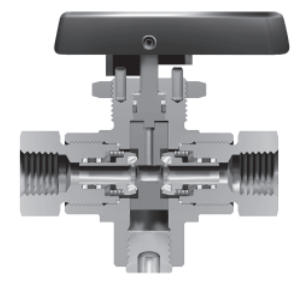

Stop check valves and lift check valves

Check valves allow fluid and gases in one-way condition. Stop check valves are used to protect boilers and other equipment. Stop check valves have two main purposes. Stop checking valves are like two checking valves in one. The internal disc is not attached to the stem. This can help to open and close the connection.